After crossing the river on the ferry from Volendam, we arrived in the small village of Marken.

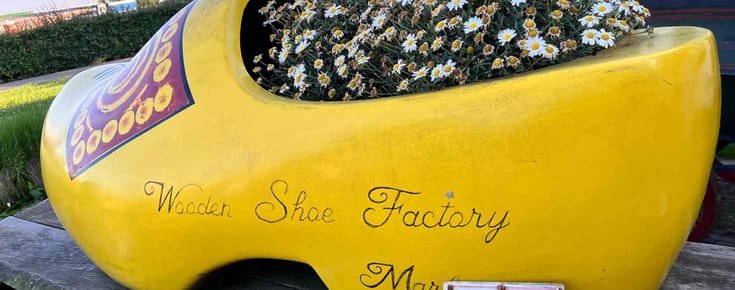

A Fascinating Tour of the Clog Factory in Marken

This island-turned-peninsula is known for its charming wooden houses and rich cultural heritage. One of the highlights of our visit was a tour of a traditional clog wooden shoe factory in Marken, where we witnessed the fascinating process of making wooden shoes from start to finish.

The Clog-Making Process

At the Wooden Shoe Factory in Marken, we were given a live demonstration by a skilled clog wooden shoe maker.

Here’s a detailed explanation of the process we saw:

1. Selecting the Wood:

The process begins with selecting the right type of wood, typically willow or poplar. These woods are chosen for their softness when freshly cut, which makes them easier to shape, and their durability once dried.

The wood is also naturally water resistant which protected the wearer’s feet from the wet Dutch climate since The Netherlands is incredibly flat!

Clogs made it possible to move across sodden ground with ease. Clogs continued to be worn by agricultural workers well into the 20th century, as their sturdiness guarded against injury.

2. Shaping the Exterior

Using a machine powered by an old steam engine from 1913, the clog maker first shapes the exterior of the shoe.

The machine, originally used for industrial purposes, is now a key part of the demonstration, showcasing both traditional and mechanical methods.

The machine follows a rotating guide, which is a plastic model of a clog. This guide ensures that the machine duplicates the exact shape of the clog every time.

3. Hollowing the Interior:

After the exterior is shaped, the interior is hollowed out using a specialized tool. This step is crucial as it ensures the shoe fits comfortably. The clog maker uses a hollowing machine that is guided by a template clog, ensuring uniformity and precision.

Our tour guide showed us the traditional tool that was used before machinery and explained that it would take 3 hours per shoe! 🤯

4. Drying:

The freshly made clogs are then set aside to dry. This can take several weeks, depending on the wood and environmental conditions. Drying is essential to harden the wood and make the clogs durable.

5. Finishing Touches:

The rough clog is then smoothed and fine-tuned. The edges are rounded, and any excess wood is trimmed. This step can also involve hand-carving intricate designs and details that make each pair unique.

6. Polishing and Painting:

Once dry, the clogs are polished and often painted.

Traditional Dutch clogs are sometimes painted with beautiful, intricate designs, adding to their aesthetic appeal.

The Gift Shop Experience

Following the demonstration, we visited the clog gift shop, which featured a wide variety of clogs in different sizes and designs.

From practical everyday wear to decorative souvenirs, the shop had it all. Although I didn’t buy any clogs due to my already maxed-out suitcase, I left with a much greater appreciation for this traditional Dutch footwear.

Multi-Lingual Demonstrations

One aspect of the tour that stood out was the effort made to accommodate visitors from all over the world. The clog maker and guide spoke numerous languages to ensure everyone could understand and appreciate the demonstration, no matter where they were from. This inclusive approach added to the overall experience, making it more enjoyable and educational for everyone.

Heading Back to Amsterdam

After our time in Marken, we boarded a bus back to Amsterdam.

The journey was a relaxing end to a day filled with cultural insights and unique experiences.

If you ever find yourself in the Netherlands, a trip to Marken to see this process firsthand is well worth it.

Additional Tips

- Interactive Experience: Many clog factories offer interactive workshops where visitors can try their hand at making a clog or decorating a pre-made one. Check if such activities are available and pre-book if possible.

- Local Cuisine: After the tour, explore local eateries in Marken. The village offers traditional Dutch dishes that can complement your cultural tour.

- Photographic Opportunities: Marken is a picturesque village with beautiful landscapes and historic buildings. Don’t forget your camera to capture the serene beauty of this unique destination.

- Nearby Attractions: Combine your visit to Marken with other nearby attractions, such as the windmills at Zaanse Schans or the fishing village of Volendam, to make the most of your day trip.

Looks like an interesting afternoon. I love the picture of the tree stump surrounded by shoes.

It was! Hahaha, I thought that was really unique too so I had to include a picture of it! 😄

Clog making is truly an art form! Doesn’t look easy to do, either…very fascinating to see how these iconic Dutch shoes are made; what a treat it was for you to experience it!

Thank you Rebecca! It was fascinating and I learned a lot more than I even anticipated from the factory visit! It’s amazing what people can make, especially before more modern tools existed!